Pistons - Reconditioning of spare parts for power plant and marine diesel engines

Pistons - Examination and repair in accordance to the engine manufacturers advise

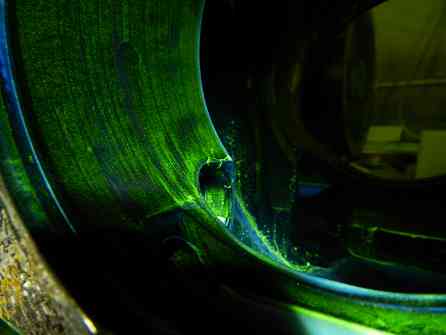

Material cracks in a piston skirt after appr. 15.000h of operation

Material cracks in a piston skirt after appr. 15.000h of operation

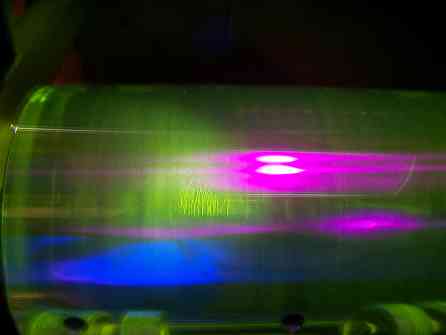

Material cracks in a piston pin after appr. 34.000h of operation

The production, as well as the overhaul of pistons, belongs to the core competence of SECO GmbH.

More than 85% of the pistons, currently in use in 4-stroke power plant and marine diesel engines, are composite pistons. These pistons are manufactured, ready for installation, by assembling a piston skirt and a piston crown. The remaining 15% of the pistons currently in use are called monobloc pistons. Monobloc pistons are made from one piece either of aluminum mould casting or nodular cast iron. Usually, pistons of this type will be replaced only; not overhauled or repaired.

But what really distinguishes the composite piston from a monobloc piston and why are these different types are existing? The reason for this is the progressive development of engine technology. In the 1960s, engines had ignition pressures of about 120 bar, which was nearly the upper limit of what was technically feasible. Today, modern power generation and marine diesel engines are reaching ignition pressures up to 240 bar. The thereby occurring stresses brought the monobloc piston designs quickly to its limits. Other, high-duty materials had to be brought into use.

A combination of steel -for the piston crown- and ductile iron -for the piston skirt- fulfilled the increased requirements at the mechanical properties. Furthermore, for the first time this combination allowed a predictable overhaul of pistons. When speaking of a composite pistons lifespan, it is actually meant only the period which the piston crown needs to reach his wear limits in accordance to the engine manufacturer specification. A binding indication when a piston crown has to be changed is usually and understandably not given by the engine manufacturers. There are too many factors and variations which influence the wear, such as: fuel quality, combustion quality, quality of separation of fuel and luboil, compliance of maintenance cycles etc.

It is true that the piston skirt is subject to a certain wear. But this wear is considerably lower than of the piston crown and therefore negligible. However, to prevent fatigue failures at piston skirts during engine operation, some engine manufacturers specify to replace the skirts within a range between 70.000 to 90.000 running hours.

From this, by correspondingly carried out FEA calculations, traceable advise of some major engine manufacturers, as a rule of thumb it can be formulated:

On every new piston skirt 2 or 3 new piston crowns can be mounted before also the piston skirt has to be replaced.

For this reason, we offer our customers the professional inspection and overhaul of his pistons. That means the exchange of piston crowns for MAN, HiMSEN, MaK and Wärtsilä engines. In this connection each piston skirt will be tested to 100% by means of magnetic particle inspection (MPI).

- After the income inspection, the pistons will be dismantled.

- The old piston crown and the mounting equipment are scrapped.

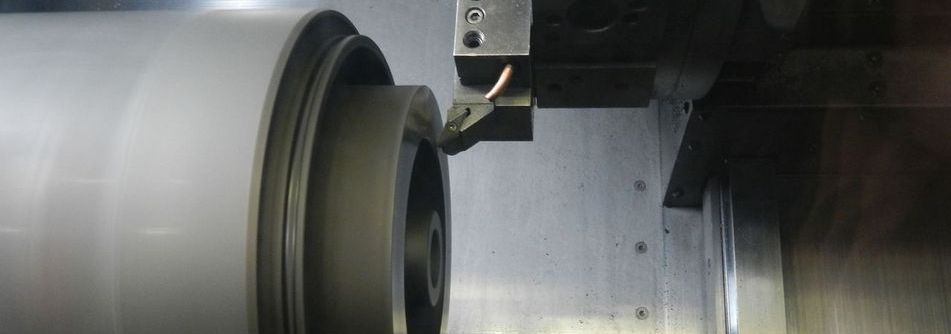

- The piston skirt is cleaned first and the old graphite layer will be removed.

- If necessary, the piston skirt will be reworked, and then tested on our MPI bench for already existing cracks.

- If cracks are found, a report is made with photos and presented to the customer for his final decision for further use.

(Our experience in this: At about 8% of all the piston skirts of Far East origin cracks were found by MPI after a short period of operation). - After the MPI has been carried out, the piston skirts get´s a new graphite coating.

- Finally a new piston crown with new mounting accessories will be mounted together with the piston skirt.

- Delivery of the piston.

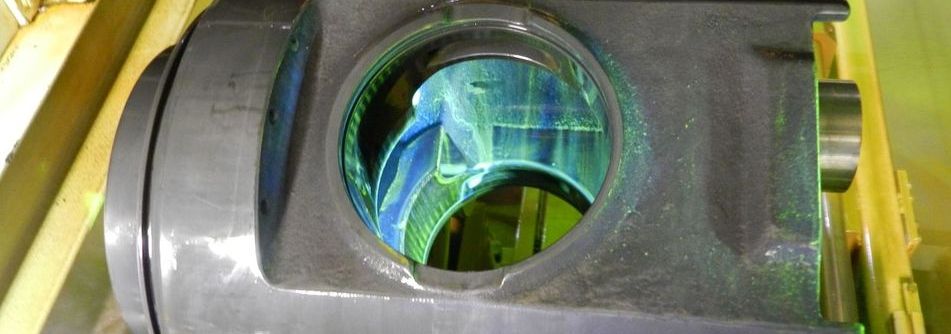

For the piston skirts, carrying out a proper and careful MPI is of importance. As a manufacturer of pistons, we are operating our own MPI bench, which was developed especially for piston crowns as well as for piston skirts. The magnetization of the piston skirt -before the MPl is carried out- covers the complete skirt and is aligned on it´s circiumference. Carried out in this way, the result of the MPI can be rated much higher than the result by of an MPI where a simple magnetization yoke is used as it is common on board or in the workshop of a power plant.

Sounds interesting? We are pleased to submit our offer to meet your requirements, ...just send us your inquiry.

MAN B&W

Piston reconditioning suitable for:

- MAN 16/24

- MAN 27/38

- MAN 32/40

- MAN 32/40CD

- MAN 48/60A

- MAN 48/60B

Hyundai Himsen

Piston reconditioning suitable for:

- Himsen 17/28

- Himsen 21/32

- Himsen H5/33

MBH-Maschinenbau Halberstadt

Piston reconditioning suitable for:

- VDS48/42

- VDS48/42AL-2

- VDG42/48

Sulzer

Piston reconditioning suitable for:

- Sulzer A20H

- Sulzer AS/AT25/30

- Sulzer ASL25/30

- Sulzer S20

- Sulzer S20U

MaK

For more information please visit the website of our sister company MMS

Marine Motor Service GmbH

Piston reconditioning suitable for:

Marine Motor Service GmbH

Piston reconditioning suitable for:

- MaK M20

- MaK M25

- MaK M32

- MaK M43

Wärtsilä

For more information please visit the website of our sister company MMS

Marine Motor Service GmbH

Piston reconditioning suitable for:

Marine Motor Service GmbH

Piston reconditioning suitable for:

- Wärtsilä VASA32

- Wärtsilä W32

- Wärtsilä W34SG

- Wärtsilä W34DF

- Wärtsilä W38A

- Wärtsilä W46A

- Wärtsilä W46B

- Wärtsilä W46C

- Wärtsilä W46D

- Wärtsilä W46GD